Custom Thermal Solutions

We’ve honed a unique way of doing things.

We call it Brilliant By Design.

Product Development Process

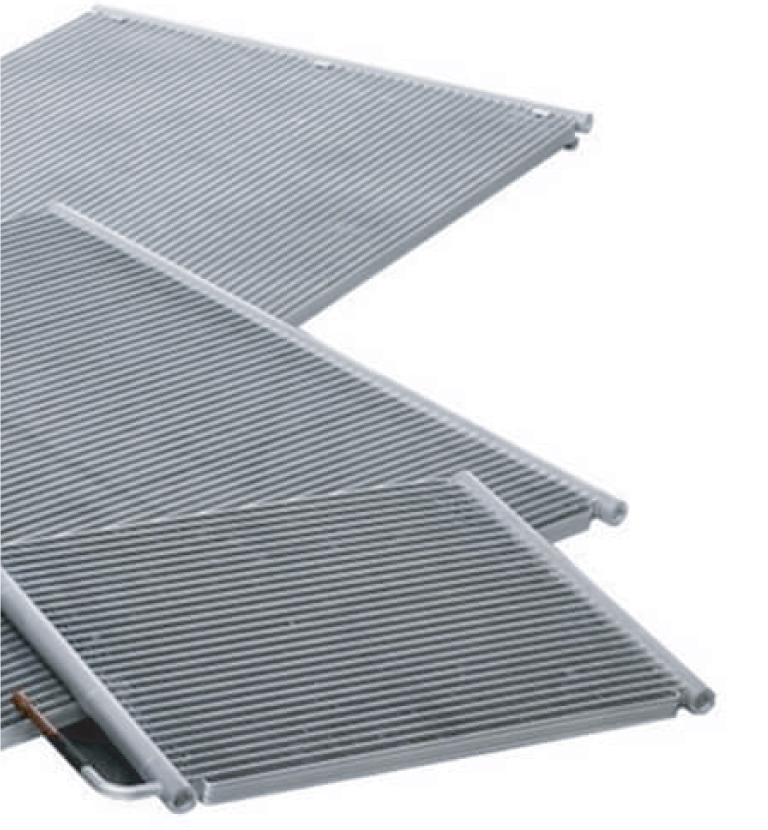

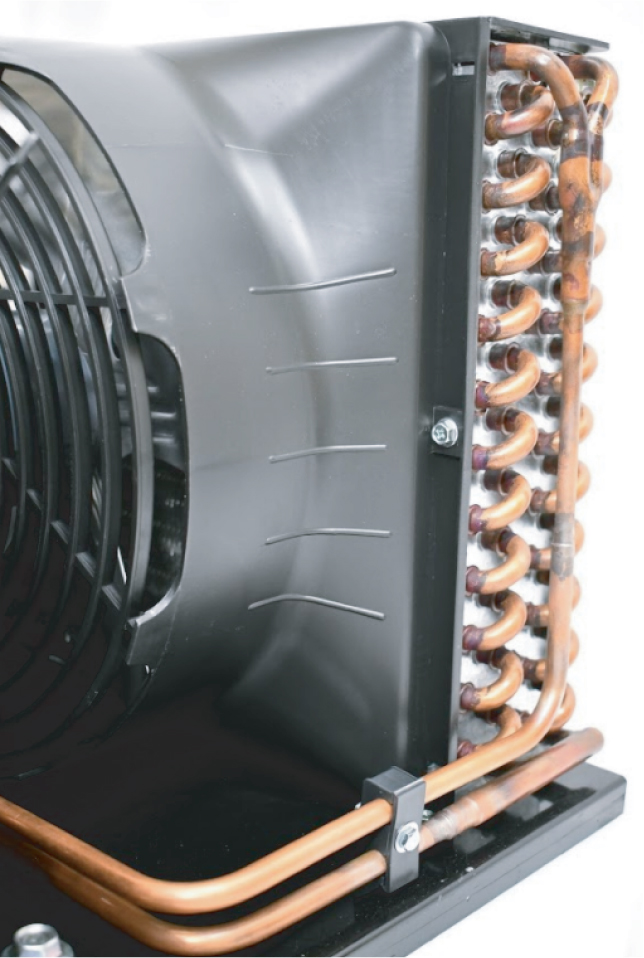

Thermocraft designs, tests, qualifies, and manufactures custom refrigeration systems that you can trust. We build subassemblies that include copper tube assemblies, brazing and complete refrigeration system and heat exchangers use in wide range of applications.

1. Discover

Deliverables:

Completing the questionnaire for refrigeration system design

Approving the project development plan (including plans for electrical, quality, systems, and mechanical)

Discovery Meeting

Audit & Research

Measurement & Evaluation

Stakeholder Engagement

2. Design

The detailed design phase starts with defining options for the product architecture, with the goal of having the greatest chance of successfully meeting product requirements while best mitigating risk. Some engineering activities in this phase include presenting options for system components, outlining the system’s overall size, sequence, and state diagrams, creating a rough solid model, and breadboarding of high-risk subsystems. Results are presented with a description of the pros, cons, and key tradeoffs for each scenario.

Deliverables:

Thermodynamic Strategy

System Component Selection

Design Mockups & Prototypes

Stakeholder Engagement & Performance Architecture Presentation

3. Create

3A. Prototype 1 Design, Build and Test

Phases 3A and 3B are typically the largest efforts in the product development journey, where the specific implementation for all disciplines occurs (mechanical and electrical design, systems, software, manufacturing, and quality). At this stage, we start the engagement with different suppliers to obtain product samples, get the main suppliers involved to provide additional manufacturing/design input on the system. Because this product will have stringent testing or certification requirements, pre-screens are performed in this phase prior to formal regulatory agency testing such as ATEX, UL, or ETL.

Deliverables:

Build a prototype sample

Electrical schematics

Layout 3D CAD files

Design failure mode, and effect analysis (FEMA)

Test plans and reports

Unit build plan – from prototype to pre-production

Initial Bill of Materials (BOM)

cost analysis, and manufacturing process identification.

Deliverables:

Updated prototypes

Update schematics and layout

3D CAD files and 2D drawings

Verification/test plans

Bill of Materials (BOM) update

Cost, build, and quality plan development

Your approval

4. Verify

This phase occurs once the detailed design is complete, and prototypes are built with manufacturing-representative quality and detail. Per customers requirements, more extensive, formal testing is performed, such as life, reliability, safety, environmental, drop, and vibration….. The design and manufacturing team at Craft work closely to enable a smooth transfer.

Deliverables:

Formal verification test reports are completed by the appropriate agencies

Final improvements are made

Production is planned

5. Activate

We take the product to mass production and our engineers are available to ensure quality is maintained and provide ongoing engineering support as needed.

Deliverables:

Mass production with a continuous improvement mindset.

Planning the next stages of product revision from the feedback received from the market.

Looking for opportunities to improve quality, efficiency.

Reduce cost

Here is an example of how

we bring ideas to life:

Markets we cover

Evolve & Grow

Original equipment manufacturers and distributors worldwide are growing their businesses with Craft today.

Bring your ideas to life!

Your business needs to perform quickly, reliably, and in step with today’s ever-changing market. You need a partner that’s as responsive as you are. Put the power of Craft to work for you.

Together we will redefine what’s possible.

Discover

Bring your ideas to life.

Craft is where engineering, technology, and manufacturing, converge to create

solutions that improve the quality of life.

By using this site, you are aware of the Terms of Use and Privacy Policy.

The material on this site may not be reproduced, distributed, transmitted, saved, or used without explicit permission from Craft Inc. This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

- Copyright © 2024 Craft Group. All rights reserved.

- Privacy Policy

- Terms of Use